Gateway Technical College (GTC) is gearing up for a major shift for Wisconsin’s workforce development with the creation of a new advanced manufacturing career pathway and certification training.

Last December, the school announced its partnership with Taiwan-based electronics manufacturer Foxconn Technology Group to assist in creating a 13,000-strong workforce for Foxconn’s liquid crystal display panel factory. Early reports are emerging on how GTC and the Wisconsin Technical College system are responding to the company’s need for skilled workers.

“Foxconn has been a great asset to us in helping us to understand the role that community and technical colleges will play, but also the types of content and curriculum that will be necessary to sustain a workforce,” GTC President Bryan Albrecht said in the Community College Daily report.

GTC is no stranger to creating public-private partnerships and industry-aligned skills-training based programs. WorkingNation featured GTC’s Horizon Center for Transportation Technology and its partnership with Snap-on Incorporated as part of its Do Something Awesome mini-documentary series.

The video and story highlight the solution for a shortage of automotive technicians and manufacturing workers through the stories of graduate Nicholas Schick and student Michael Wittrock. At the Horizon Center, both Schick and Wittrock trained with the latest in Snap-on tools and diagnostic equipment. Students can earn stackable industry-recognized certifications through GTC as well as participate in the paid MOPAR CAP apprenticeship program.

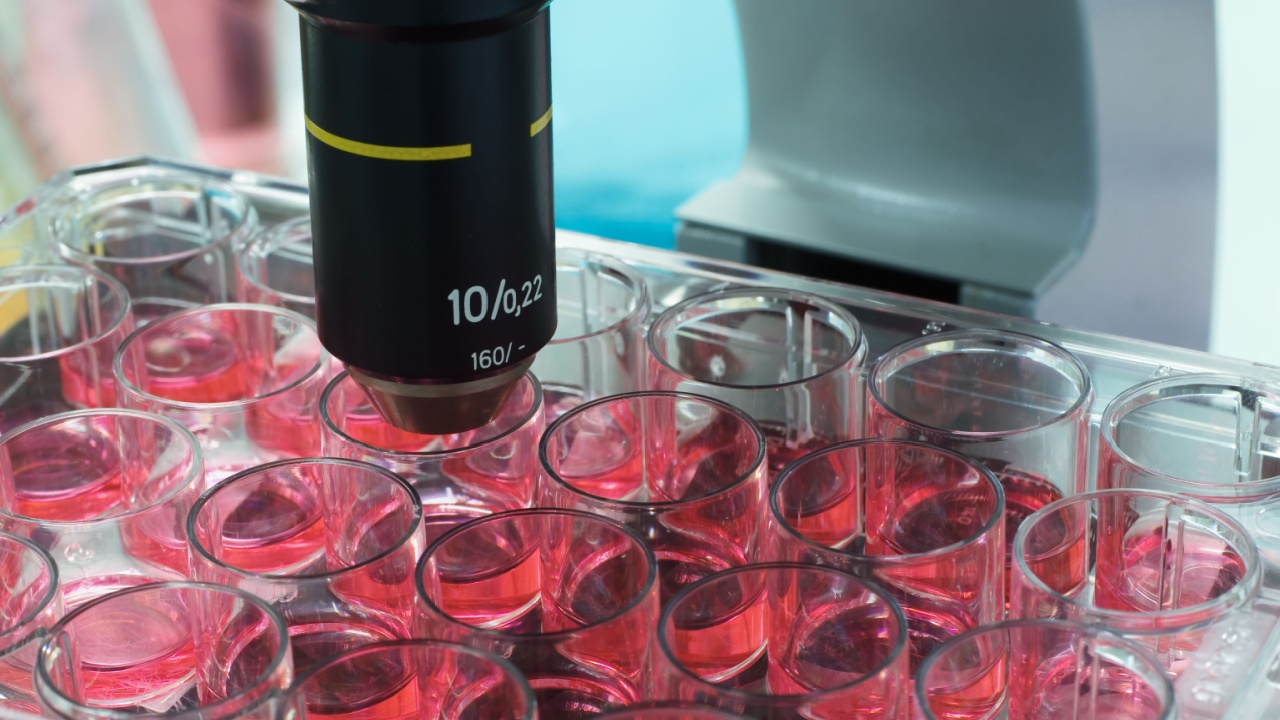

As rapid advances in clean energy, digital and automation technologies change the automotive industry and drive demand for skilled workers, manufacturing is also undergoing a similar transition during what is called Industry 4.0 or the Fourth Industrial Revolution. Factories are becoming smarter and more efficient even before they are built, thanks to robotics, artificial intelligence and Internet of Things tech. Repetitive low-skilled tasks are being automated, leading to fewer workers on factory floors.

According to a World Economic Forum report released last week, 1.4 million jobs in the U.S. are threatened with obsolescence due to this technological disruption. Transitioning low-skilled manufacturing workers into roles in electronics installation requires reskilling. And more jobs in this growing sector require a post-secondary certificate, according to a Wisconsin State Journal report on the state’s skilled labor shortage.

Those who can successfully ascend to these skills can make an hourly wage at or above a “living wage” in the state. Graduates with a two-year associate degree in electronic engineering can expect to make between $20-25 an hour.

To adapt to the demands of Industry 4.0, Albrecht told the Racine Journal-Times that the school’s new career pathway is being developed with Foxconn and area high schools to create a seamless workforce pipeline. He noted that the partnerships would keep the “programs as current as possible” to best prepare the workforce for “emerging job markets.”

Foxconn began its partnership with GTC last September and have worked out of the school’s SC Johnson Integrated and Manufacturing Engineering Technology Center in Sturtevant. That same month, GTC submitted a $5 million grant proposal to expand the iMET center and add the capacity to train an additional 1,000 students each semester.

Responding to the immediate demand for skilled workers has also thrust GTC to the forefront of a consortium of Wisconsin’s universities and technical colleges. Albrecht told the Community College Daily that the consortium can continue the career pathway for students into four-year engineering degrees and beyond. Foxconn estimated that it will need 2,400 high skilled workers with advanced degrees.

“We work with all of the regional providers of higher education to make sure that we’re providing, first of all, the right curriculum and then, second, that that curriculum is ‘pathwayed’ into advanced careers,” Albrecht said.

Classes for the Industry 4.0 career pathway could begin as early as the Fall 2018 semester. GTC is hosting an Industry 4.0 open house in February for high school students and families to explore this new career pathway.

For more information on the program, check out the GTC website and proposal for this curriculum by clicking here.

Join the Conversation: Tell us your thoughts about GTC’s new program on our Facebook page.