Electric cars still represent a fraction of the cars sold around the world, but sales growth in the EV market is accelerating. The number of electric vehicles doubled globally in 2018 to five million, according to a study released last year, and the EV industry is expected to continue to expand. Here in the United States, it employs about 200,000 people, with large hubs of work in seven states.

While many plants are shuttered due to the COVID-19 pandemic, the demand for workers is expected to pick up in the second half of the year in order for EV carmakers to meet new CO2 emissions mandates in China and the European Union.

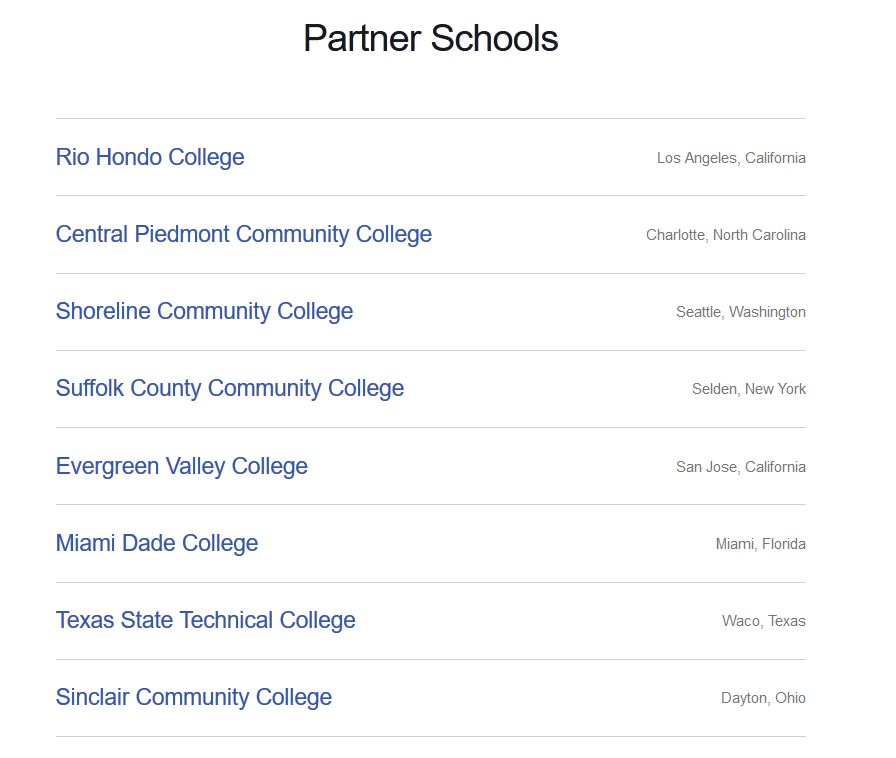

Tesla is known for innovation in its electric vehicles. The company also is innovating the way it builds its workforce of technicians. The Tesla START program is working with eight community colleges throughout the nation, training students to become technicians for the company’s line of electric vehicles.

The START Program

Tony Sciarra is Senior Program Manager for Workforce Development and Education at Tesla. He tells WorkingNation the idea for START—the student automotive training program—came when the service training team was trying to build an internship program. His department was focused on working with vocational schools and community colleges.

The two joined forces to work together and test the idea out. The program evolved through several different training cycles and the results were so successful it was brought fully online in 2018.

The Ideal Candidate

Sciarra says START looks for candidates who already have a fundamental grasp of electrical theory.

“We take candidates who are either graduates from the auto tech programs or have come from the military or this is their second career and they’ve already been in the field or they were already in some sort of technical field like aeronautics or infrastructure or some sort of infrastructure maintenance. And so, they would essentially be a technician on their own. We then run them through this 12-week training program where we make them advanced technicians.”

According to Sciarra, “We’re really trying to get to about 85 to 90 percent of the actual material that most of our technicians would learn through our specific trainings.”

That includes learning about shop flow, what each model car does, the function of each part, subsystems throughout the car, breaking down the car and building it back up again, etc. Students work an average of 50 hours per week in classroom and hands-on training.

“In that time, the instructor really is looking for how do they work in a team, how do they respond to problems? They have a one-on-one pretty much every week with that instructor to really kind of determine what it is that they’ve been struggling with or working on. Also, the instructor will realize it too in some of the quizzes that they take. So, everything is tracked. Every aspect of what they’re doing is tracked.”

“Usually around the midway point. We have a good idea of where they would like to go, or where the business needs really are,” says Sciarra. “And then my team will then spool up that hiring process where we start to work with the field to figure out where’s our biggest business needs, or who has headcount or who would really like these candidates.”

Students receive a stipend that works out to roughly a dollar above minimum wage, based upon the area of the country in which they’re training. Upon completion, students are awarded a certificate which is good in any state.

In addition, those who are offered work are either relocated to where their skills are needed, or they stay local. The rate for technicians is anywhere from $19 to $28 per hour depending upon location. The package includes medical benefits and an opportunity for equity in the company.

A Community Partner

The relationship with community colleges is a vital part of the Tesla START program.

“We work hand-in-hand with the school to really essentially become like an added program. They open up their space, they open up their infrastructure. If they’ve got things that they can let us use, we’ll use that,” Sciarra notes. “Otherwise we take equipment from other service centers that aren’t being used or that have been scaled down or stuff that’s still really good but we’re working at upgrading something else.”

“We bring it to these schools along with probably five or six different cars and our own server so that the cars are tied to a Tesla server. The students are working off of a Tesla server. So, there’s no lapse when they go to work at an actual service center, they understand how everything works.”

One advantage for Tesla is that it’s using its own curriculum in the community colleges.

“The schools themselves that host our programs are mainly a host, but they are chosen for a myriad of reasons. Either they’ve got a really strong auto tech program or they’re in a good market. We’ve got a good strong working relationship with the administration already. Or they’re really a school that’s constantly trying to push the envelope. Because one of the tough things that a lot of trade programs have in keeping up with the times and keeping up with technology is the bureaucratic nature of the education system.”

“It’s really hard for them to be in lock step with technology when it takes sometimes a year or two to get a curriculum approved. Technology right now as we know, moves so much faster than that. So, this was kind of our way of bridging the gap, so to speak, because our curriculum doesn’t need to be approved by anyone. And we can change it on the fly as fast as possible.”

Skilled Jobs Created at a Local Level

Sciarra says the START program has allowed the company to connect with the various communities in which the colleges are located by making a skilled trade a viable, and more attractive, option for the people who live there.

“Your kid is, yeah, they’re turning a wrench. But look what else they’ve started working on. This is a rolling mobile app platform. The biggest tool we give them is a laptop. These students, these mechanics, are talking to the cars through laptops. You know, they’re getting them to do things. They can take a VIN number and diagnose a car right away by just pulling up some information, and then they can talk to people who’ve worked on it previously. If they’ve found a fix, they can reach out to engineering directly, and be like, ‘Hey, we’re, we’re seeing this. We found a fix.’”

Sciarra calls skilled trade programs like auto tech important, noting that Tesla is doing a lot of community outreach to high schools in program areas. Tesla also is working on an externship with local instructors to learn how it is to work on electric cars.

“I would love to continue to emphasize, this is why this program is so awesome is because it’s just highlighting how amazing infrastructure already is and how we as a society need to be making that shift and looking more seriously at skilled trade.”

START and COVID-19

The COVID-19 pandemic has forced some changes to Tesla’s production and delivery in the U.S. The company furloughed workers and its sales force and is expected to get back to work in May.

Meanwhile, the START program, because of closed schools, has gone virtual.

Automotive service is considered an essential industry which allows students to be considered service employees. That’s allowed the hands-on portion of their training to move to Tesla service and training centers.

Sciarra emphasizes that everything is being done at a social distance setting. In addition, new classes that were scheduled to start in May or June are being pushed back to a time that coincides with the ramp up of Tesla automotive production.

Sciarra says if anything the pandemic has provided an opportunity to calibrate the program, to figure out what’s working, what should change, what can be done differently, and where else in the company a program like START can be applied.