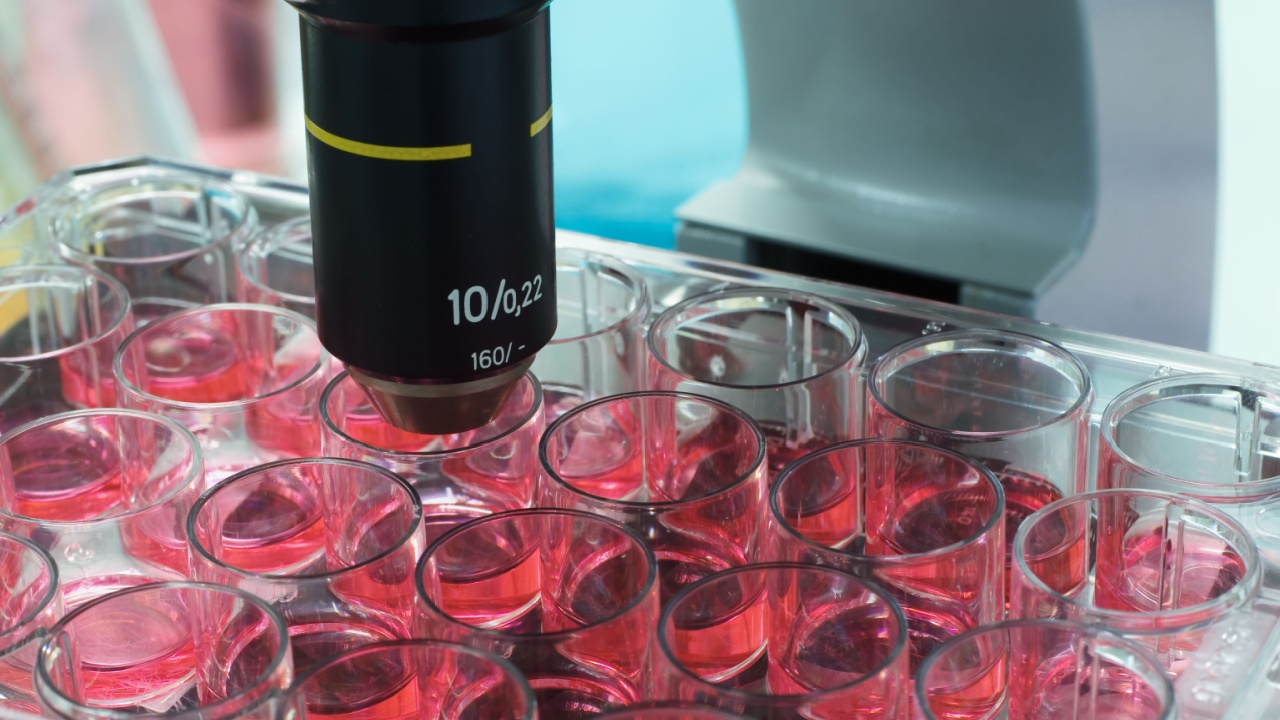

Arkansas aims to create a hub of biomanufacturing talent with a new program led by the University of Arkansas (U of A). In as little as two weeks, Arkansans can earn a biomanufacturing micro-credential which can qualify them for jobs earning between $50,000 to $60,000 a year.

“Northwest Arkansas is a fast-growing, vibrant economy attracting world-class talent with our art and culinary amenities, and outdoor recreation opportunities,” says Toby Teeter, director of U of A’s Collaborative. “However, our region is underrepresented in the biotech sector. We want to offer our community high-paying career opportunities in this sector.”

The Collaborative is both a physical space and an innovation center, education, and research initiative that works with northwest Arkansas industries located in Bentonville, 30 miles north of the main campus.

Teeter joined forces with Tara Dryer, senior managing director of the U of A Global Campus Professional and Workforce Development, to create the university’s first program of its kind – the BioAR Train Biomanufacturing Workforce Initiative (BTBWI). The duo received a federal grant of close to a half million dollars through the U.S. Department of Commerce’s Economic Development Administration’s 2023 STEM Talent Challenge. The university is providing more than a half million dollars in matching funds.

Increasing the development of bio-industry credentials is a national priority. In Arkansas, the importance of biomanufacturing is two-fold, according to Teeter – it is one of the fastest growing segments of biotech and med tech industries and is part of the fast-growing class of life-saving medicines. Academia, workforce development, and companies want to be a part of this effort.

“We have Arkansas-based private equity and venture capital investing in biomanufacturing companies from around the world, including SymBiosis Capital Management here in Bentonville,” Teeter says. “As their discoveries require industrial manufacturing scale, we hope to attract contract biomanufacturers to relocate, expand, or establish in Arkansas to service the growing list of biomanufacturing startups with Arkansas ties. These large-scale biomanufacturing employers will require a trained workforce to meet these needs.”

“We are thrilled that the U of A has received this generous grant to train new workers for Arkansas’ growing biomanufacturing sector,” says SymBiosis Managing Partner Chidozie Ugwumba in a statement. “In the coming years, we expect innovative companies will come to our state to benefit from the skilled biomanufacturing professionals this program will produce.”

Teeter and Dryer traveled to other universities including Texas A&M’s National Center for Therapeutic Manufacturing to observe how similar workforce development centers are converting low-skill workers into performing biomanufacturing workers in less than three weeks.

The program will offer two tracts. The first will be a set of self-paced learning modules delivered online. It will be widely available across the state through partnerships with high schools, community colleges, and regional workforce centers across Arkansas. The second tract is an instructor-led hybrid curriculum that will leverage virtual reality equipment and software to replicate specific operations of machinery and biomanufacturing processes. The first VR-based biomanufacturing center will be located at the Collaborative in Bentonville. Two additional centers will eventually open in other areas of the state.

The curriculum will be available to high school graduates and workers from other fields with no prior manufacturing experience. It could be incorporated into existing high school science classes. Reaching underserved communities iss also a component of the grant.

“We hope to diversify our economy and add this fast-growing field to our state,” Teeter says. “Retaining and growing our workforce is a key economic development goal for our state. We don’t want our talent seeking biotech jobs leaving our state.”

The credential can help participants qualify for technician jobs working in pharmaceutical, food and beverage, cosmetics, and other fields. The online modules will be free. The “first few” cohorts of students will receive a full scholarship for the virtual reality portion.

The center at the Collaborative is expected to open by the end of March. The goal is to certify more than a hundred workers during the 24-month grant period and place them with biomanufacturing companies relocating or expanding into Arkansas. The hope is that employers will also use the training pipeline to train their workforce and cover the training costs.

“The transformation of our region in the space of biomanufacturing will be a collaboration between the University, business and industry, and other stakeholders,” Dryer says. “We each play a critical role in making this a success within our region. The workforce training is just one piece of the puzzle, and it is exciting to watch it all unfold.”