Wisconsin still prides itself on its automotive manufacturing lifeblood which courses along Interstate 94 between Milwaukee and Chicago. Right in the middle is Kenosha and the Gateway Technical College Horizon Center for Transportation Technology, where decades of automotive experience are matched with the modern tools of the trade.

Gateway graduate Nicholas Schick and student Michael Wittrock would have separate paths which led them to repairing and maintaining cars for a living. Thanks to Gateway’s partnerships with Snap-on Incorporated, Fiat Chrysler Automobiles North America and the MOPAR CAP program, they entered the workforce with an adaptable skill set ready to handle today’s advanced automotive technology.

“When I combine the work ethic I have learned throughout life, with the strong foundation of what GTC instilled in me, I am able to dive in deeper and work harder in finding the root of the problem,” said Schick, who graduated in 2015 and is now a lead tech at Silver Lake Auto Service in Silver Lake, Wis.

Gateway’s partnerships with automotive industry leaders have produced skilled technicians at the Horizon Center over the last decade. The school’s President & CEO Dr. Bryan Albrecht utilized a federal grant to upgrade his school’s automotive education program and forged Gateway’s public-private partnership with Snap-on to align the program with industry needs.

“Snap-on and Gateway Community College partner together because cooperation between technical colleges and businesses are an essential way to match curriculum to the skills that are needed,” Snap-on Chairman and Chief Executive Officer Nick Pinchuk said.

The partnership blossomed with the opening of the Horizon Center in 2007. It instantly set a national standard because of its world-class facility and innovative public-private educational model. Gateway would help close a local skills gap by giving students access to certification training to make them valuable assets after graduation.

“When I took a look at some of the automotive programs that we had at Gateway, they were not meeting the expectations of our employers,” Albrecht said, “So when I reached out to Snap-on, it was really to help us understand how we could make sure that our content and curriculum was going to serve the needs of students.”

Getting Your Hands Dirty

Schick would need an educator that could accommodate his lack of experience.

He had a love of auto racing, but beyond seeing “cool” mechanics “getting their hands dirty” at a local garage as a kid, fixing cars was not his destiny after high school. He said in an email interview that he developed his work ethic while building homes with his father then working as a custodian. He even tried accounting classes at Gateway, thinking that his strong math skills could lead to a desk job.

But as Schick turned 20 and he settled down with his wife, he understood that becoming a provider meant securing better work, one that could utilize his problem-solving skills and his desire to keep working with his hands.

“I became more aware that I would need to find a new job or career that would be able to support my wife and, eventually, if we had kids. I once again looked at the typical office or desk type jobs, but never felt good about those careers for me,” Schick said.

He decided to give the automotive program a look and though he had never changed a wheel mount or diagnosed an electrical problem, he found a home at Gateway. Schick had access to the latest Snap-on tools and certified instructors who, after retirement from regional factories and auto shops, were sharing their expertise with the next generation of techs.

Wittrock, on the other hand, had a lifelong admiration for classic cars and was fixing his middle school principal’s car after his dad brought him into the world of auto repair at an early age.

What he needed was an educational program that would keep him on a path straight to employment. Gateway’s automotive program extends a talent pipeline by reaching down to the regional high schools, including Wittrock’s William Horlick High in Racine.

Horlick boasts in its course catalog that the school will produce an entire graduating class which is “career-ready or college-ready” through an extensive dual enrollment curriculum relationship with Gateway. Horlick’s auto program allowed Wittrock to get real-world instruction through Gateway which made the Horizon Center the logical step following graduation.

“When he went to high school he took shop classes right away,” said Wittrock’s mother, Tina, “He scooted to the top of the class because he has that natural ability.”

Gateway offers an instructional environment that is flexible for students from different walks of life. A typical class is comprised of about 75 percent of work-ready students over the age of 25 and the rest of students out of high school. For students like Schick, there are night classes available as they continue to work during the day. For recent high school grads, they are immersed in a shop that demographically mirrors their future workplaces.

“I think that’s a key aspect of this whole program, that students can start while they’re in high school and then transfer those [skills] directly into the college,” Albrecht said.

Hands-on with Snap-on

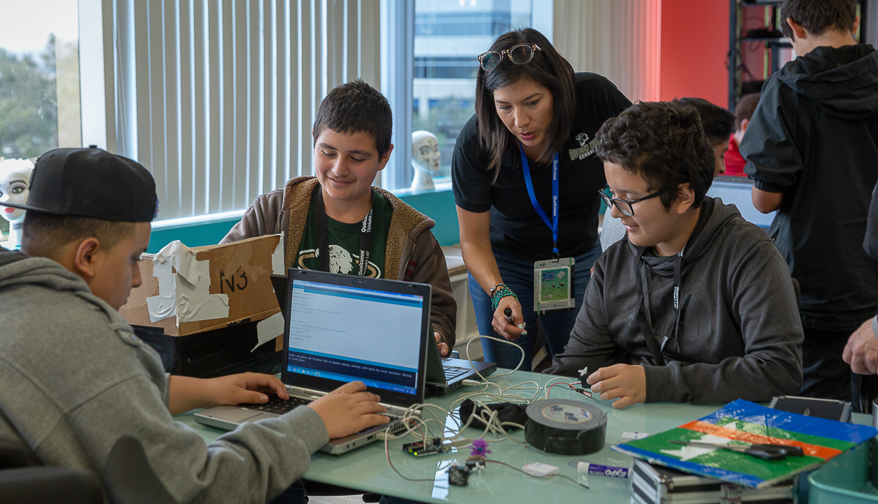

The Horizon Center, which houses Gateway’s automotive and aeronautical training programs, provides a state of the art classroom where students like Schick and Wittrock receive hands-on instruction on the latest in Snap-on diagnostic instruments like ETHOS and the laptop-based VERUS PRO. Successful completion of the Snap-on coursework can result in resume-boosting and stackable NC3 certifications.

Today’s automobiles have become crammed with the latest in tech, from pedestrian sensors that engage predictive braking mechanisms to high-performance electrical motors. The center was created with this in mind and is preparing technicians for the automotive jobs of the future. With the school’s addition of the 12,800-square foot Diesel and Advanced Propulsion facility in 2010, students are able to achieve Snap-on certifications to work with the latest in green technology.

“To think about all-electric vehicles or autonomous vehicles, it’s not the same,” John A. Fox, Director of the FCA Performance Institute said of today’s automotive landscape, “If you wanted your son or daughter to work in a career where they’re on the front edge of technology, I could make the case that your son or daughter should be an automotive technician.”

Snap-on’s Certification Centers can be found nationwide at more than 100 post-secondary schools, including Gateway, and each receives the benefit of having a steady supply of Snap-on tools. Schick said that he never worried about having to rely on outdated or well-worn equipment.

“I could learn how to use some of the more expensive tools and I never had to worry about trying to make do with what I had. I always had the right tool for the job and was able to focus on learning,” Schick said.

MOPAR CAP Keeps the Talent Pipeline Flowing

The Gateway/Snap-on automotive program also allows its students to earn while they learn through its partnership with the MOPAR Career Automotive Program. While in school, students can work with FCA-approved equipment and gain experience through apprenticeships at area FCA dealerships where they will become certified to work on Fiat Chrysler vehicles.

“Technicians are gaining in age. Those individuals are now retiring,” Fox said, “Our MOPAR CAP local program at Gateway is a key program for us to help identify future technicians to supply that talent that we need.”

Upon graduation, students gain the MOPAR CAP certification and become eligible to work within FCA dealerships nationwide. After Wittrock completed his apprenticeship, he landed a junior technician position at Martin’s Chrysler Dodge Jeep & Ram in Union Grove.

“The Gateway/Snap-on program has definitely changed my life,” Wittrock said.

From high school to the workforce, Wittrock has been helped along the way by a streamlined, industry-certified program that maximized his talents at a lower cost than a traditional four-year college. One of his instructors, Gateway NC3 coordinator Matt Janisin, said that Wittrock has all that he needs to succeed in life.

“He really has leveraged all the opportunities available to him and I have full confidence he’ll leave here and be a world-class technician,” Janisin said.

The Drive to Succeed

Snap-on’s mission to modernize automotive technical education is creating the next generation of worker and makes it an attractive career pathway for students who may be put off by outmoded notions of vocational training. For Snap-on CEO Pinchuk, it’s about restoring automotive work to prominence and showing younger people that it has become a high-tech field of study.

“When you walk into one of these classrooms and you see the equipment and you see the environment, it screams the reinforcement of the dignity and specialness of the work those people do,” Snap-on’s Pinchuk said.

For Schick, coming home to his wife and kids after a hard day at the shop is proof enough that the stigma of auto tech work is just a tired stereotype. He said he would like to continue building his skills to prepare for a future that may not include the combustion engine and pass on what he learned to the next generation.

“I would love to be able to teach others how to take pride in one of the trade careers, “ Schick said, “And [teach them] how to take a step back and look at something and feel good knowing that they have repaired a vehicle to the highest standards and see a customer drive away happy knowing they and their vehicle were treated with the utmost respect.”