The nation relies on thousands of qualified aviation mechanics to keep our planes flying, but a skills gap in this sector is about to face the headwinds of a Federal Aviation Administration-imposed deadline to modernize.

Dreamline Aviation in Van Nuys, California is on target to have its fleet upgraded before this deadline, thanks to the work of its subsidiary, RTS Aircraft Services, and its team of mechanics and avionics technicians.

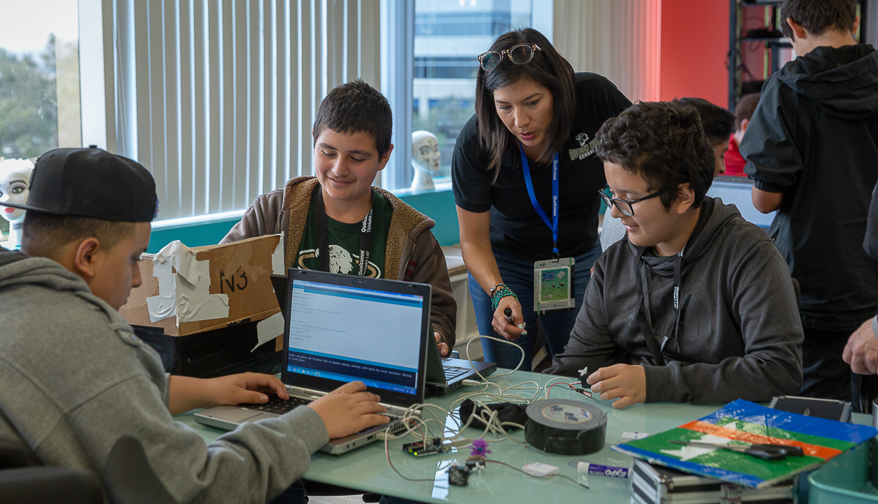

They have found success in developing a workforce by training mechanics from scratch, like mechanic’s apprentice and avionics technician Isaac Gonzalez, the subject of our Do Something Awesome video, The Shift is Now.

Gonzalez’s story is one that must be replicated across the nation, as a talent shortage threatens to keep many planes grounded. Right now, there are not enough technicians for the thousands of general aviation aircraft that will need new digital technology which will lower fuel costs and increase safety.

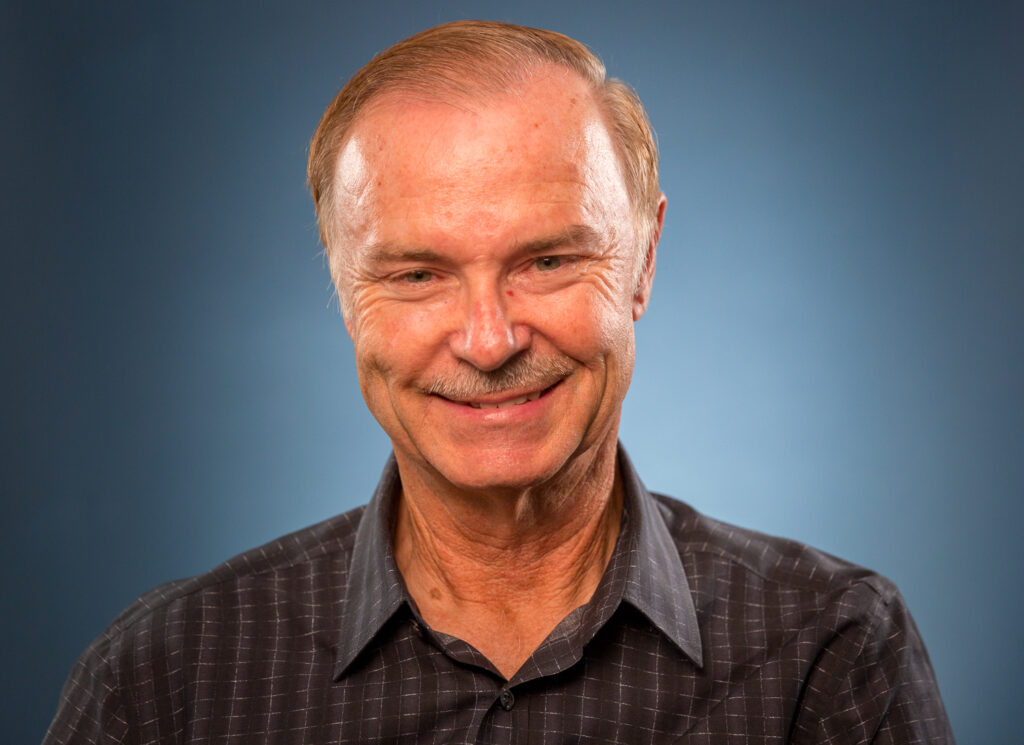

Dreamline Aviation President and Co-Founder Mark L. Schmaltz said that the industry doesn’t have the training resources to meet the growing demand for technicians.

“There’s very little in the way of training. Almost the whole industry has functioned for 30 years pretty much on on-the-job training. Aside from what comes out of the military, the civilian industry is just very limited in what training is available,” Mark L. Schmaltz said.

The implementation of the Next Generation Air Transportation System, NextGen, mandates that all general aviation aircraft must upgrade to GPS-based long-range tracking communications. The FAA said that the ABS-D Out (Automatic Dependent Surveillance-Broadcast) systems are going into as many as 160,000 aircraft. The costs, depending on the aircraft, can cost from ten to hundreds of thousands of dollars.

The upgrades are important because they allow planes to land in not-so-favorable conditions and replaces ground-based radar technology. With ADS-B technology, air traffic controllers from the smallest airports to the largest and pilots will have pinpoint accuracy of a plane’s location, altitude, and speed. Dreamline’s Corporate Controller and charter pilot Mark A. Schmaltz, the co-founder’s son, said that ADS-B is a major upgrade over the old technology.

“[The] ADS-B system would be a generation beyond that where we’re incorporating a satellite system in conjunction with a ground-based system, which when you add those together makes a more accurate position. We get a better position in space in a 3D as opposed to a 2D, which is kind of the old GPS-style system,” said Mark A. Schmaltz.

Including RTS Aircraft Services, only 340 avionics shops nationwide can perform the upgrades, leading to critical logistics decisions in managing the work hours, downtime and installation schedules. However, the rate of installation has remained slow as owners wait for cheaper technology or an extension of the Jan. 1, 2020 deadline, though unlikely. There could be gridlock if the industry cannot replace retiring workers and train its current workforce to add digital skills to their toolbox.

Navigating the Shift

Gonzalez’s path to working on Dreamline’s managed fleet of 15 aircraft represents one way the industry has brought in new talent. Gonzalez was introduced to the Dreamline president through a family friend and bonded over a mutual appreciation of classic car restoration. Though Gonzalez knew more about auto maintenance than aviation maintenance, he had enough skills that could translate into a new field.

Gonzalez said that growing up near an airport in Oxnard, California is what stoked his interest in aviation.

“As a child, I’d sit in the backyard and watch airplanes fly overhead and I thought that was really cool. My dad and I went to a few airshows, and he’d buy me model airplanes and I built them,” Gonzalez said.

Yet his career pathway out of high school didn’t go right into a trade program for aviation maintenance. He tried community college, taking general education classes with the plan to move on to a four-year college. He had no defined plan so he set off on a journey to figure out his future.

“It was just kind of monotonous and I really didn’t have an idea of what I wanted to do. I went and traveled around, got a better insight on life,” said Gonzalez. “At that point, I met my girlfriend, now wife, and we decided to go travel around the world basically for about a year.”

Upon returning to California, Gonzalez said that he would pair his mechanical aptitude with a trade.

An aircraft maintenance career is a smart choice for someone without a college degree. A trained mechanic with FAA airframe and power plant certifications can earn a median income of around $60,000, according to the Bureau of Labor Statistics.

Dreamline’s president said that Gonzalez was the right candidate to fill an apprenticeship position.

“We brought him, we interviewed him, we made him an offer and set about to turn him from someone who barely knew the front of an airplane from the back into someone who could be an avionics technician,” said Mark L. Schmaltz.

Gonzalez began working for RTS on the Dreamline fleet in 2016. Training in avionics is typically done in the hangar, where an apprentice would take direct instruction from someone with the skills in this sector.

“Avionics is a bit mysterious in the fact that there’s a set group of people that know about it and if you want to learn about avionics, you go to those people and you kind of study under them, and then you learn about it. Other than that, you go to seminars,” Gonzalez said.

This was how Gonzalez learned to install the critical information systems that relay real-time information to the pilot and ground-level air traffic control.

“It’s pilot-static systems, it’s altimeters, it’s a lot of stuff and so those systems, or units, they all interface, meaning that they talk to each other, they give information to one another, and it’s displayed to the pilot,” Gonzalez said.

He got his ADS-B training through Aircraft Electronics Association (AEA) seminars, which is the only way for technicians to gain this qualification. Mark L. Schmaltz said that the AEA was great for someone like Gonzalez as it gave him the experience to learn wiring, soldering and basic electronics including to ADS-B equipment installation.

Gonzalez said that he has noticed the lack of qualified technicians across the industry and the increase in demand for ADS-B installs.

“There has been an increase. And I know that the sooner we get to 2020, more people are going to come pouring in,” Gonzalez said. He added that the low amount of repair stations like the one RTS Aircraft Services maintains will contribute to a logistics backlog.

Both Gonzalez and the Dreamline president said that the industry needs an electronics certification along the lines of the airframe and power plant certifications to spur more training opportunities for high demand electronics and digital skills.

“Mark was saying to me on the phone that he’d hire more technicians if he could find qualified technicians, but because there is [no certification], it’s really hard. It’s like you’ve got to train up,” Gonzalez said.

A Race to the Finish Line

The Dreamline president said that there’s going to be a “mad rush” as the deadline draws near.

“It’s just going to outstrip all the existing capacity for the workflow. I think we’re going to end up with potentially thousands of airplanes grounded after the deadline while the inevitable happens,” Mark L. Schmaltz said. He explained that the industry needs a better solution to train candidates in a shorter time period.

So far, Gonzalez has performed four ADS-B installations in addition to his general maintenance and fabrication duties. He said that he is building on his avionics experience and is pursuing his airframe and power plant certifications through the North Valley Occupational Center’s aviation program. By working toward his maintenance certification, he believes he has a pathway that could lead him toward an engineering degree.

“Progression is always big for me. I want to advance, I want to learn more and apply that knowledge. As far as a career, maybe seeking out something in aeronautical engineering would be cool,” Gonzalez said.

Going on his journey, from community college to navigating the world, he’s gained the insight he was searching for. Gonzalez said he is more driven now that he knows what he wants and the route to get him there. In a time when the aviation industry needs more workers like Gonzalez, it also must create workforce training solutions to find them.